Great to see you here! Please register and create your new account.

Produkte wurde erfolgreich in den Warenkorb gelegt

Your Basket

Order for an additionaland you will receive your order with free shipping.

Subtotal

Loading...

Checkout using your account

Checkout as a new customer

Creating an account has many benefits:

- See order and shipping status

- Track order history

- Check out faster

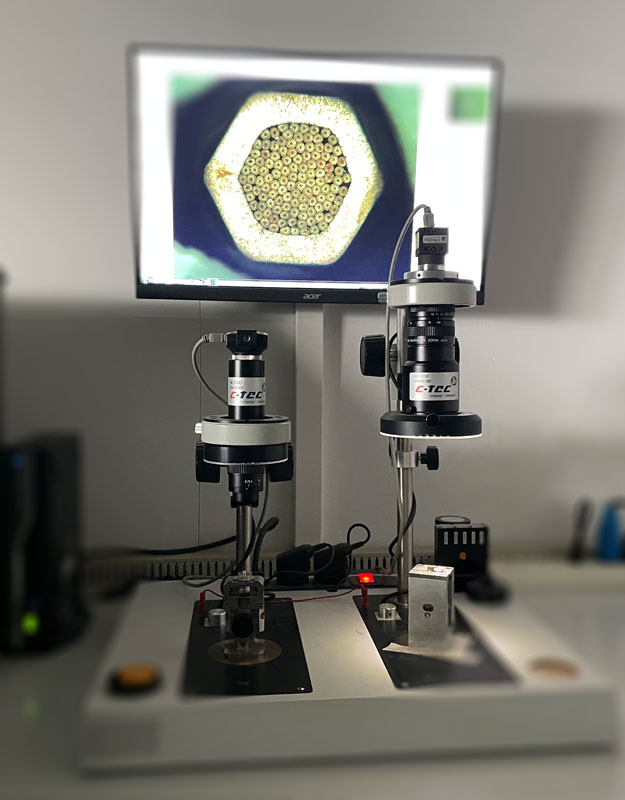

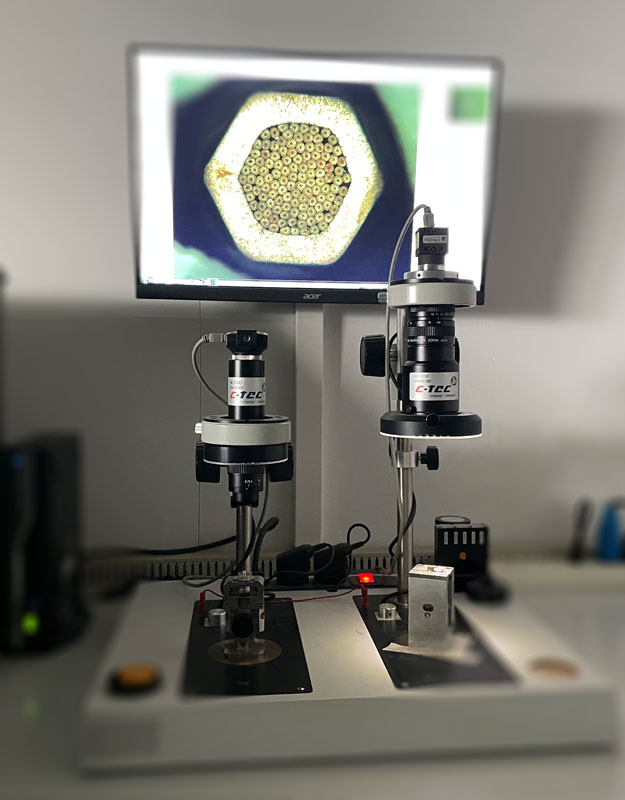

Grinding pattern analysis

For safe and reliable connections

The highest quality is essential in cable assembly because only perfect connections guarantee reliable function, especially at high currents and under extreme conditions such as vibrations. With micrograph analysis, Otto Schoch AG offers a precise testing method to analyse and ensure the quality of crimp connections with microscopic precision.

Why is micrograph analysis important?

During the production process, quality defects that are often invisible to the naked eye can arise due to tool wear, temperature differences, material changes or tool changes. A micrograph examination uncovers such defects and provides valuable insights into the quality of the crimp connection.

The advantages of micrograph analysis:

- Precise quality control: microscopic examination of the crimping

- Optimisation of connections: ensuring a gas-tight and even crimping

- Reduction of line resistance: the better the pressing, the lower the electrical resistance

- Long-term reliability: prevents failures due to inadequate connections

What is being tested in the micrograph analysis?

The analysis provides detailed information about:

- Consistency of crimping: How accurately was the contact crimped?

- Gas-tightness: Is the connection sufficiently tight to prevent corrosion?

- Quality of crimping tools: Are the tools used suitable for the wire type and contact size?

- Stranded wire and gap sections: How well has the wire been integrated into the contact?

These tests are crucial to qualify crimp connections and ensure consistently high quality.

When is a cross-section analysis required?

We particularly recommend a cross-section analysis

- For new crimp connections: every new connection should be tested to detect errors at an early stage.

- After tool changes: to ensure that the new tools are working correctly.

- When changing materials: Different materials can influence the crimping result.

- For regular quality control: To detect wear or deviations in the production process.

Our service – precision you can rely on

Otto Schoch AG offers you comprehensive testing of crimping quality using the latest micrograph analysis. Our service includes:

- Analysis of crimp quality: microscopic examination of the crimp

- Measurement of strand and gap sections: detailed analysis of wire integration

- Consultancy and optimisation: recommendations for improving the connection and tool configuration

With our expertise and state-of-the-art technology, we ensure that your crimp connections meet the highest requirements – for maximum safety, reliability and efficiency.

Get the quality your applications demand!

Contact us today and benefit from our professional crimp cross-section analysis service. Together, we will ensure that your cable assemblies meet the highest standards.

We are pleased to help you

Do you have any questions about our products or would you like personalised advice?

Our experienced team will be happy to help you - whether for technical information, product enquiries or customised solutions. We look forward to hearing from you and providing you with competent and personalised support.

- Price:

- Actual Price:

Loading...