Great to see you here! Please register and create your new account.

Produkte wurde erfolgreich in den Warenkorb gelegt

Your Basket

Order for an additionaland you will receive your order with free shipping.

Subtotal

Loading...

Checkout using your account

Checkout as a new customer

Creating an account has many benefits:

- See order and shipping status

- Track order history

- Check out faster

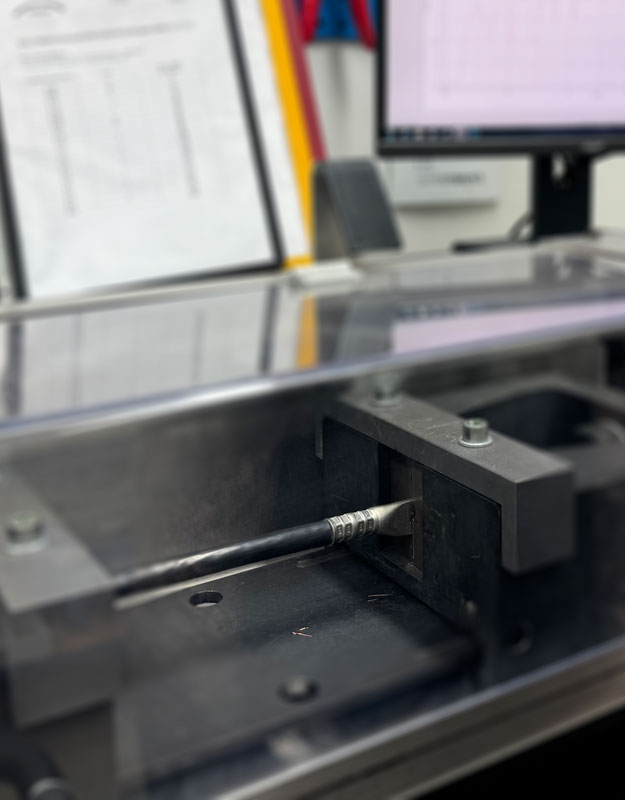

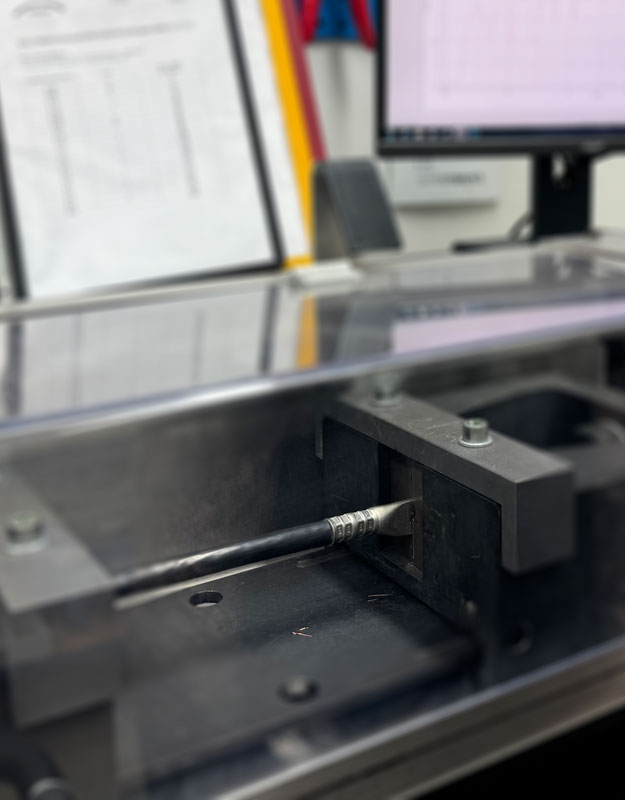

Extraction test

Safety and quality for your crimp connections

A high-quality and reliable crimp connection is at the heart of every cable assembly. Proper pressing of the contacts onto the strands ensures a long-lasting, gas-tight, and secure connection that can withstand even the most demanding conditions. With cable pull-out tests, Otto Schoch AG offers a professional method for checking the mechanical strength and quality of your crimp connections – in accordance with international standards and the highest requirements.

Why are cable pull-out tests so important?

During the crimping process, insufficient or excessive pressing force can cause serious problems:

- Insufficient pressing: If insufficient force is applied or an oversized crimping tool is used, oxygen can penetrate the fine-wired conductors. This leads to corrosion, increased contact resistance and potential loosening of the connection.

- Excessive compression: Excessive compression or a crimping tool that is too small can impermissibly reduce the cross-section of the conductors, reduce the current carrying capacity or even shear off individual conductors. This can render the connection unusable and endanger safety.

Cable pull-out tests measure the mechanical force required to separate a crimp connection. This ensures that the connection meets international standards and provides an optimal hold.

When are cable pull-out tests required?

We recommend performing pull-out tests in particular:

- For new connections: At the beginning of a project to test the quality of new cables, contacts, and tools.

- After tool changes: To ensure that new tools work correctly and meet standards.

- When changing materials: Different materials can affect the crimping result.

- For regular quality control: To detect deviations or wear in the production process at an early stage.

Our method – precision and reliability

Otto Schoch AG tests your crimp connections using the most modern processes and equipment. Our cable pull-out tests include:

- Measurement of the separation force: Determining the mechanical force required to disconnect the connection.

- Testing for international standards: Ensuring that the connection meets the applicable standards and specifications.

We also recommend a cross-section analysis

- Extraction test in combination with cross-section analysis: For a comprehensive evaluation of crimp quality and optimisation of tools, contact sizes and wire cross sections.

Your advantages at a glance

- Safety and reliability: Prevent failures due to inadequate connections.

- Quality assurance: Ensure that your crimp connections meet international standards.

- Optimisation potential: Identify weaknesses and improve your processes.

- Durability: Guarantee gas-tight connections and reduce the risk of corrosion.

Together for the highest quality

With cable pull-out tests from Otto Schoch AG, you receive a comprehensive analysis and evaluation of your crimp connections. Our experts support you in optimising your connections and ensuring maximum safety and efficiency.

Contact us today to learn more about our services or to schedule an appointment for your cable pull-out tests. Trust in our experience and precision – for connections that deliver what they promise!

We are pleased to help you

Do you have any questions about our products or would you like personalised advice?

Our experienced team will be happy to help you - whether for technical information, product enquiries or customised solutions. We look forward to hearing from you and providing you with competent and personalised support.

- Price:

- Actual Price:

Loading...